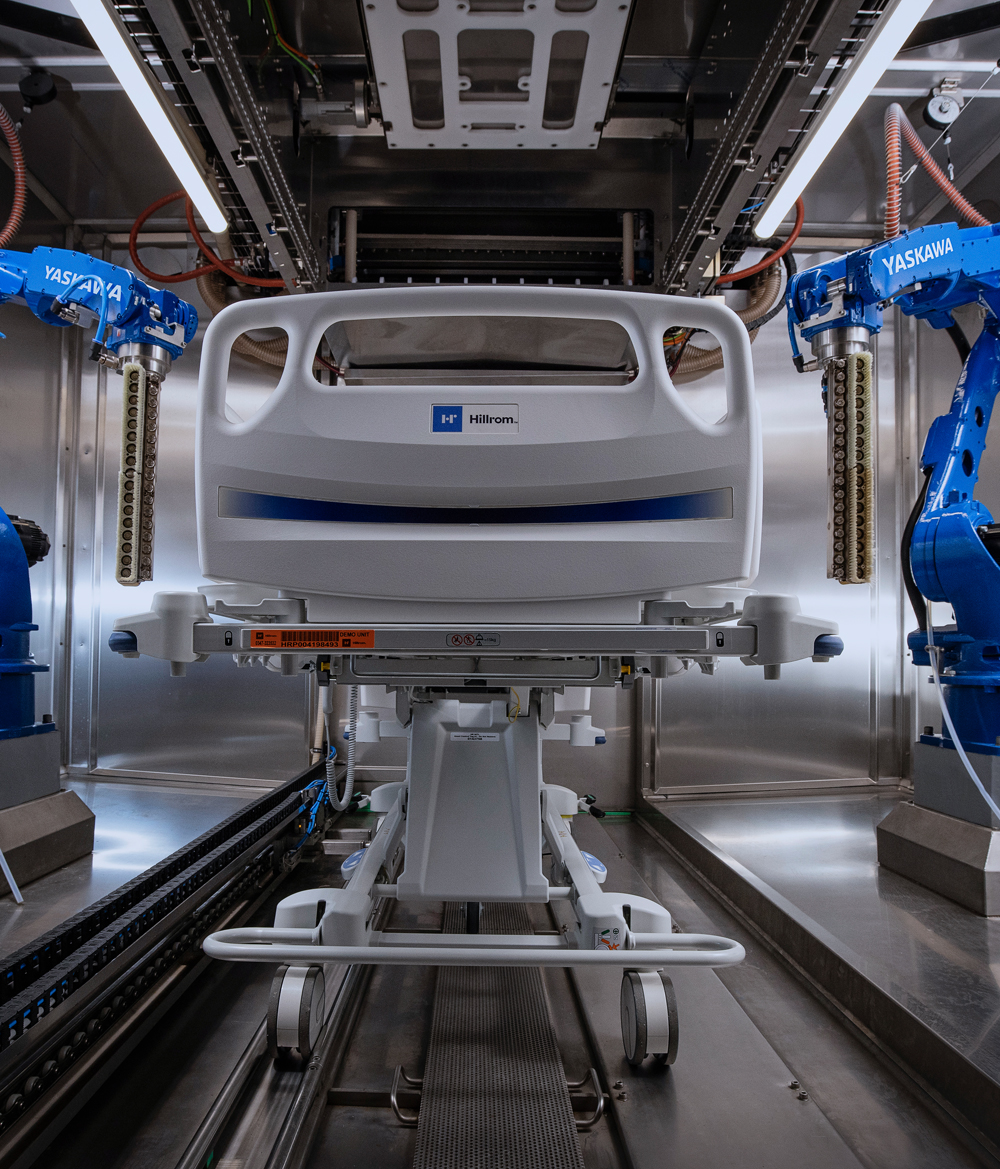

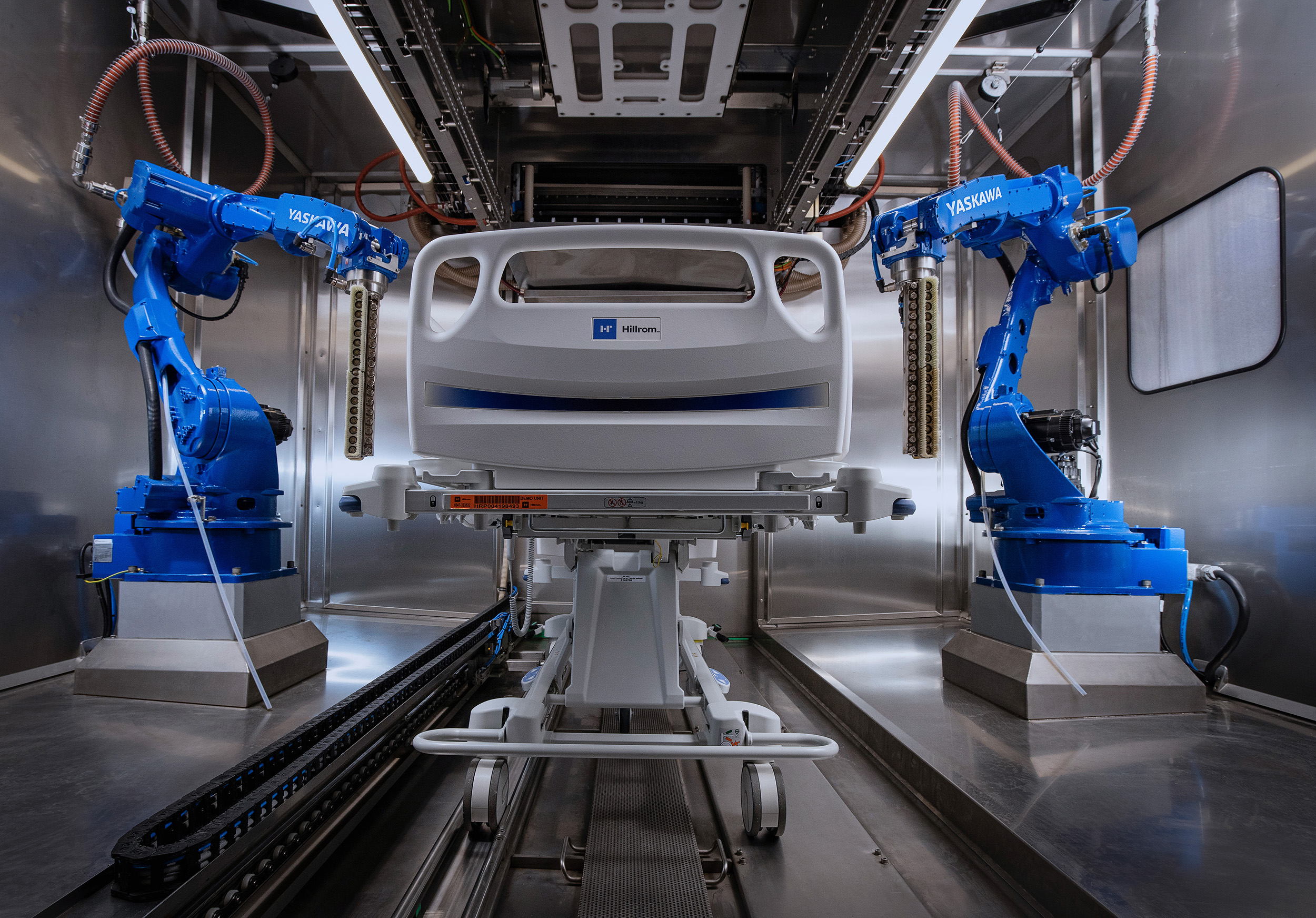

The VDS (Validated Disinfection System) is the first solution in the world to validate and disinfect hospital beds and mattresses without using chemicals. The use of steam cleaning and robot technology guarantees a constant and controlled quality of the result: every bed or mattress is guaranteed to be clean and ready-for-use in six to eight minutes.

Traditional bed washing machines are often labour-intensive, consume a lot of water and energy and use chemicals. The VDS proves that there is another way. This innovative system makes it possible to clean and disinfect hospital beds, mattresses and medical devices using steam and precision robots, without chemicals or added physical strain on the staff. In the VDS, the mattress is automatically lifted from the bed and cleaned, disinfected and dried all the way around.

If a hospital bed is equipped with the latest communication technologies, like a QR code or an RFID tag? The VDS is then able to collect management information at bed level. This way, we can closely monitor the status of every bed in the hospital and continue to deliver quality.

Every hospital wants to provide the best care in the safest environment. For example, by focusing on infection prevention. However, infectious diseases are becoming increasingly difficult to control: more and more microorganisms that are resistant to antibiotics are circulating.

The key lies in improving hygiene measures. The approach to cleaning in a hospital plays an important role in this. According to the WHO guidelines, mechanical cleaning of hospital beds is preferable to manual cleaning, because automated processes are of a consistent quality: the result is always the same.

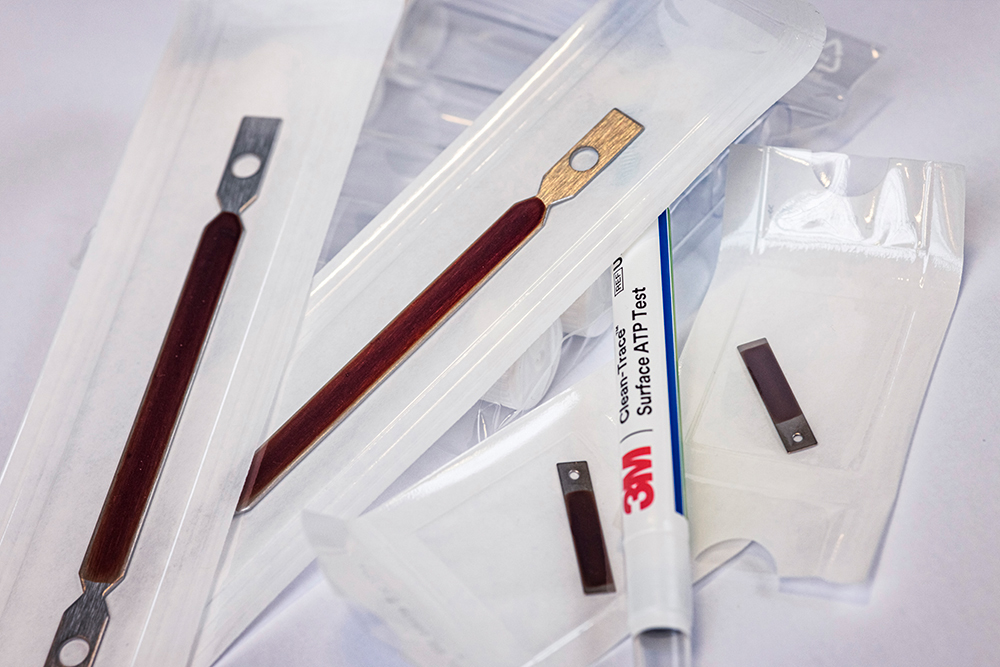

For example, the VDS always follows the same program, which reproduces the same cleaning and disinfection process. Validated measurements show that the contact temperature is at least 95 degrees Celsius, so we realize an A0-60 that is optionally adjustable. This means that the VDS meets the criteria set out by ISO-15883-6, the standard for disinfectant washing machines for healthcare equipment. After a cleaning cycle, the bed is immediately dried and cooled, so that it can be reused straightaway – guaranteed clean and safe before use.

Sustainability is also an important topic in healthcare. How can we also provide the best care in the safest possible environment in the future? The VDS is a sustainable choice. Our innovative system cleans and disinfects hospital beds, mattresses and medical equipment using steam and precision robots, without chemicals or unnecessary physical strain for the staff. Because attention to a healthy working environment is part of a sustainable future.

The VDS is designed with ergonomics in mind for employees. In traditional washing machines, the mattress often has to be lifted off the bed, but in the VDS, the mattress is automatically lifted off the bed and cleaned, disinfected and dried all the way around.

Due to the ergonomic design, the VDS can be operated by one person. In addition, the VDS consumes a minimum amount of energy, steam and compressed air. CO2 emissions are reduced by at least 35% compared to other machines. Chemicals or other chemical additives are not used. Steam and precision robots ensure a validated result. This way, you’re keeping an eye on the future with the VDS, for people as well as the environment.

Take a quick look at our whitepaper.

Technological developments are happening at lightning speed. Nowadays, there are smart beds with, for example, an integrated scale and connectivity, which can be used to send patient data directly to the electronic patient record. However, these technologies in smart beds mean they cannot be cleaned in traditional bedwashers, that use a lot of water and chemicals.

The VDS is the only solution in the world that makes it possible to machine clean and disinfect high-tech IPX4 beds. In doing so, the VDS offers the best of both worlds: hospitals can now opt for innovative beds with smart functionalities without compromising on the quality of the cleaning and disinfection of the bed. This offers a range of opportunities.